Understanding Industrial Gas Manometers: A Comprehensive Guide

What is a Manometer?

Industrial gas manometers are crucial tools used to measure the pressure of gases within a system. They provide accurate readings, ensuring the safety and efficiency of operations. Manometers come in various types, each suited for specific applications, making them versatile instruments in industrial settings.

A basic understanding of the design and functionality of manometers can significantly enhance their application in industries. They are typically filled with a liquid, like mercury or water, which reacts to pressure changes, indicating measurements on a calibrated scale.

Types of Manometers

U-Tube Manometers

U-tube manometers are among the simplest and most commonly used types. They consist of a U-shaped tube filled with a liquid. The difference in liquid levels in the two arms of the tube indicates the pressure. They are renowned for their accuracy and are often used in laboratory settings.

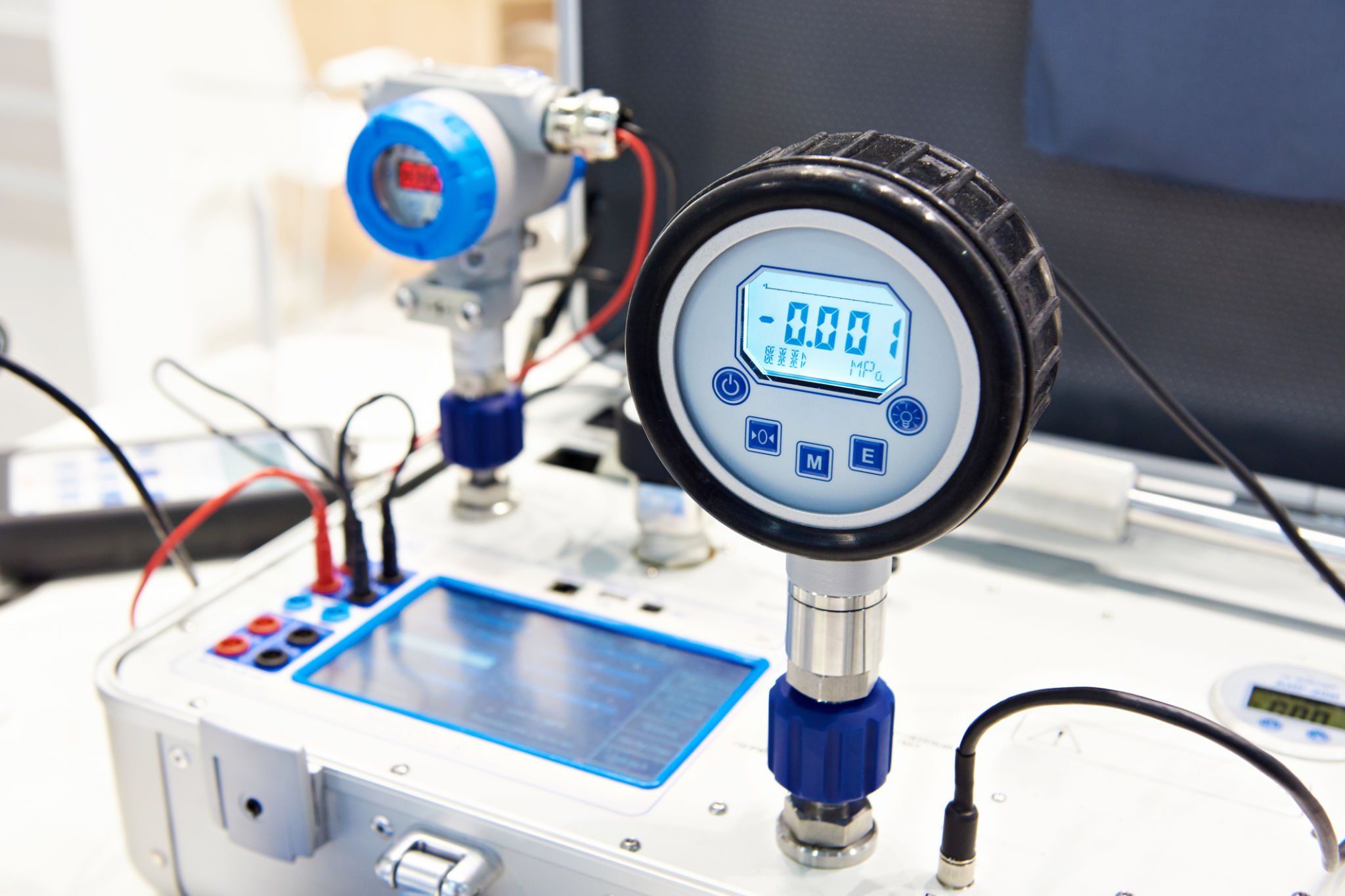

Digital Manometers

Digital manometers are advanced devices that provide digital readouts of pressure measurements. They are user-friendly and often equipped with additional features such as data logging and remote monitoring. These are ideal for applications requiring high accuracy and real-time data analysis.

Applications of Industrial Gas Manometers

Industrial gas manometers are used across various sectors, including HVAC systems, chemical processing, and manufacturing. They help in maintaining optimal pressure levels, which is crucial for operational efficiency and safety.

By monitoring gas pressure, these devices prevent leaks and system failures, ensuring that equipment functions within specified parameters. This not only enhances safety but also extends the lifespan of machinery.

Choosing the Right Manometer

Selecting the appropriate manometer depends on several factors, such as the type of gas, pressure range, and required accuracy. It's essential to understand the specific needs of your application to choose a manometer that meets those requirements.

- Type of Gas: Consider whether the gas is corrosive or non-corrosive.

- Pressure Range: Choose a manometer that can handle the expected pressure levels.

- Accuracy: Determine the precision needed for your application.

Maintenance and Calibration

Regular maintenance and calibration of manometers are vital to ensure their accuracy and longevity. Calibration involves adjusting the device to standards, ensuring that readings are precise. It's recommended to perform calibration at regular intervals, depending on the frequency of use.

Proper maintenance includes checking for leaks, cleaning the device, and ensuring no obstructions affect the liquid levels in analog manometers. Digital manometers may require software updates and battery checks.

Conclusion

Understanding and utilizing industrial gas manometers effectively can significantly enhance the safety and efficiency of industrial operations. By choosing the right type and maintaining it properly, businesses can ensure accurate pressure readings, leading to better performance and reduced risks.